Recently, the production workshop of Luoyang Hongyuan Bearing Co., Ltd. (Hongyuan Bearing for short), located in Matun Town, Mengjin County, has been busy. The machines are running briskly, and brand-new and shiny precision bearings of different sizes are freshly released and will soon be sent to Europe.

"In the subdivision of high-precision special bearings, Hongyuan occupies 80% of the domestic market share, and 50% of its products are exported to 18 countries and regions." Zhou Shuzhou, general manager of Hongyuan Bearings, introduced that the rotation accuracy of their bearings is two microns , equivalent to 1/30 of the diameter of a human hair.

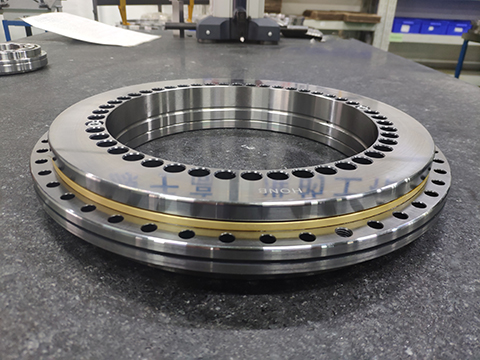

Where does such confidence come from? Time back to 2007. At that time, the widely used YRT turntable bearings in the industrial field were basically monopolized by Schaeffler in Germany. YRT rotary table bearings are used in high-end machine tools for processing high-precision parts, with high precision requirements and high market threshold. Zhou Shuzhou and his team realized that if they could develop a product with performance similar to Schaeffler's, they would be able to take the initiative in the market.

After a year of market research, the Hongyuan Bearing R&D team began to invest in the R&D and trial production of domestic YRT bearings. This is undoubtedly a huge challenge for Hongyuan Bearing, which has just been established for two years. Through the continuous efforts of the R&D team, the news of the initial successful development of domestic YRT bearings spread quickly, and some large companies came to visit one after another. DMG, the largest machine tool company in Europe, extended an "olive branch" to Hongyuan Bearings.

In 2008, the first sample of YRT rotary table bearing produced by Hongyuan Bearing was sent to Europe. One month later, DMG company sent product feedback, requiring the rotation accuracy of the bearing to reach the European standard of 2 microns, but it is not easy to reach 4 microns according to the domestic standard.

It is not easy to meet the requirements of DMG. If you don’t have special technical equipment, you can transform it yourself; if you don’t have ready-made testing equipment, you can produce it yourself; It passed the acceptance.

In this way, Hongyuan Bearing broke the long-term domestic monopoly of similar foreign products through continuous technological innovation, and quickly occupied the market segment.

"Technological innovation can enable enterprises to stand on the pyramid in the industry." Zhou Shuzhou said that it is the general trend for industrial robots to replace manual participation in manufacturing. As one of the core components of industrial robots, the harmonic reducer bearings used in robot joints have been seized by Japan, Germany and other countries almost all of the market, but the products of these companies are expensive and the delivery cycle is long.

In the face of new market opportunities, at the beginning of 2010, Hongyuan Bearing strategically set its sights on the research and development of industrial robot bearings, and successively invested nearly 40 million yuan in technology research and development and market development. After countless improvements and innovations, Hongyuan Bearing now has a complete set of core technologies and production processes for the R&D and production of robotic bearings. Some performance indicators of the products are higher than international standards, and many technical and technological levels are internationally leading, accounting for 90% of domestic harmonics. Reducer bearing market.

In recent years, the company has established a bearing testing center and a bearing experiment center with a complete quality control system; it has invested more than 50 million yuan in product technology upgrades and intelligent transformation of production lines, and implemented "machine replacement" in key positions to greatly improve production efficiency.

"We will continue to make efforts in the field of precision bearings, and continue to deepen and refine." Zhou Shuzhou said that in the next step, Hongyuan Bearing will rely on the informatization and automation of the manufacturing process to improve production levels, and gradually build digital workshops and smart factories. Expand market share. Strive to achieve sales revenue of 250 million yuan in 2022 and 500 million yuan in 2025, create an intelligent manufacturing model, and further expand domestic and overseas market shares.