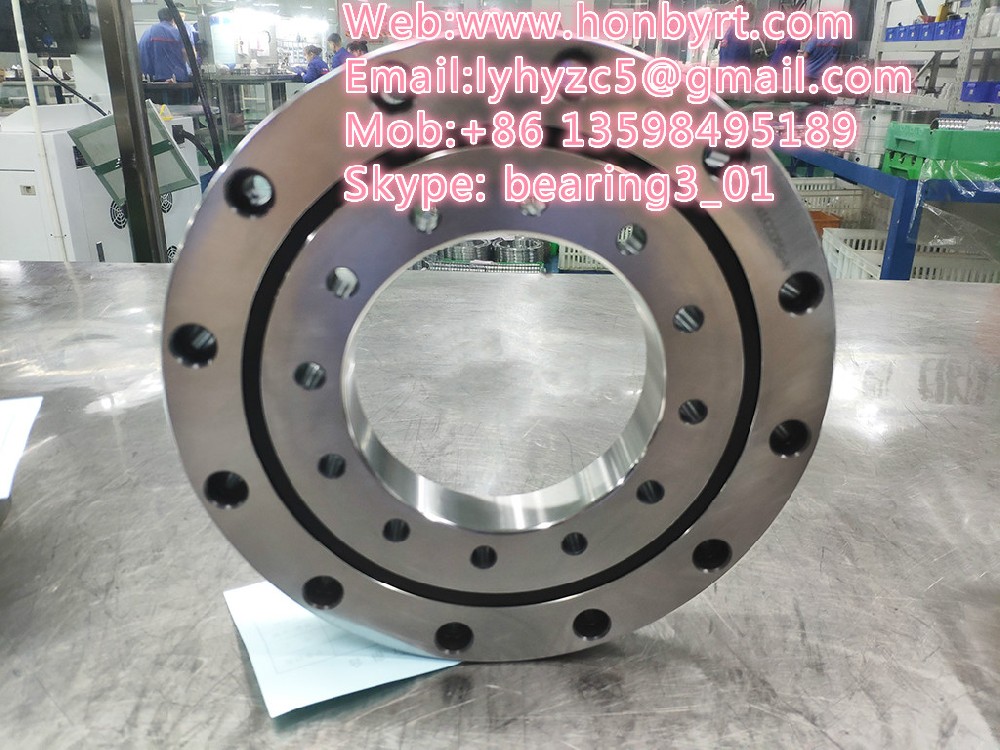

With the rapid development and maturity of domestic high-precision processing equipment, more and more high-precision CNC processing equipment such as CNC indexing discs, vertical machining centers, vertical lathes, and grinding machines have abandoned traditional designs and adopted better crossovers. roller bearings. It has the characteristics of high rotation accuracy and speed, large bearing capacity, small size, strong rigidity, etc. It has a wide range of uses and incomparable advantages of other bearings.

Crossed roller bearings are also called crossed roller bearings. The rolling elements generally use cylindrical rollers or tapered rollers to arrange crosswise on the raceway. The rollers are separated by cages or spacers. The arrangement of rollers enables a single bearing to withstand various loads such as axial load, radial load and overturning moment. Compared with traditional structural bearings, the rigidity is increased by 3-4 times. It is suitable for various industrial rotating parts, rotating worktables and other applications.