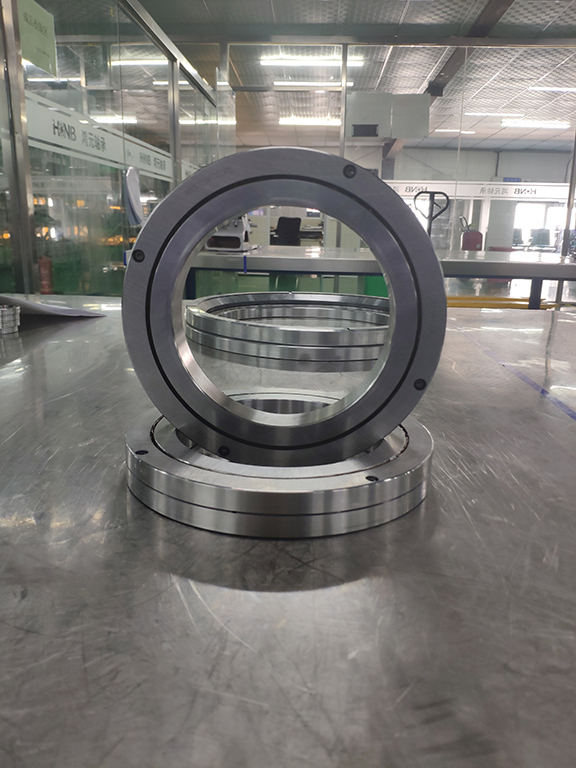

According to the structure, crossed roller bearings can be divided into: integral inner ring, split outer ring, integral outer ring, split inner ring and integral inner and outer ring.

1. Cylindrical roller bearing: The rolling elements of the cross roller bearing are cylindrical rollers, which are vertically arranged in a V-shaped raceway at 90 degrees to each other, and the rollers are separated by spacers. This structure can withstand various loads such as axial load, radial load and overturning load.

Applicable to: joints or rotating parts of industrial robots, rotating tables of machining centers, rotating parts of manipulators, precision rotating tables, medical equipment, measuring instruments, etc.

2. Tapered roller bearings: Crossed tapered roller bearings are a variant of crossed cylindrical roller bearings. The tapered rollers are arranged horizontally. Each roller is perpendicular to the adjacent rollers. The intersection of the extension lines of the rolling body generatrix should be located in the bearing in the turning line.

Can be widely used in: high-speed vertical lathes, high-precision workbenches, vertical boring machines, grinding machine spindles, etc.