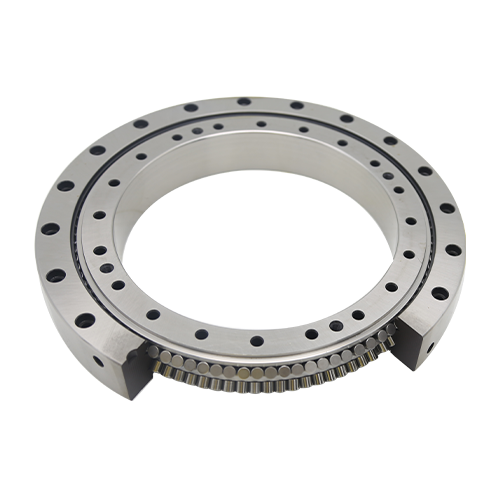

The working principle of rolling bearings developed based on sliding bearings is to replace sliding friction with rolling friction. They are generally composed of two rings, a set of rolling elements and a cage. They are highly versatile, standardized and highly serialized. High mechanical base parts. Since various machines have different working conditions, various requirements are put forward for rolling bearings in terms of load capacity, structure and performance. For this reason, rolling bearings need to have various structures. However, the most basic structure is composed of inner ring, outer ring, rolling elements and cage.

The functions of various parts in bearings are:

For radial bearings, the inner ring is usually a tight fit with the shaft and runs together with the shaft, and the outer ring is usually a transition fit with the bearing seat or mechanical housing hole to play a supporting role. However, in some cases, the outer ring is also running, and the inner ring is fixed to play a supporting role, or both the inner ring and the outer ring are running at the same time. For thrust bearings, the shaft ring is a tight fit with the shaft and moves together, and the seat ring is a transition fit with the bearing seat or mechanical housing hole and plays a supporting role. The rolling elements (steel balls, rollers or needle rollers) are usually evenly arranged between the two rings in the bearing with the help of a cage for rolling motion. Its shape, size and number directly affect the load capacity and performance of the bearing. In addition to evenly separating the rolling elements, the cage can also guide the rotation of the rolling elements and improve the internal lubrication performance of the bearing.