As an important part of machine tools, the turntable has always been the focus of machine tool design. As a key component for carrying workpieces, the turntable's rotation accuracy, rigidity and composite load-bearing capacity directly affect the processing performance of the machine tool. Among them, the selection of bearings plays a direct and decisive role. The traditional solution for turntable bearings generally uses two or more sets of radial and thrust bearings in combination, in order to enable the turntable to simultaneously withstand axial loads, radial loads and overturning moments. Although this solution is mature, it also has disadvantages such as complex turntable structure design and inconvenient bearing installation and maintenance.

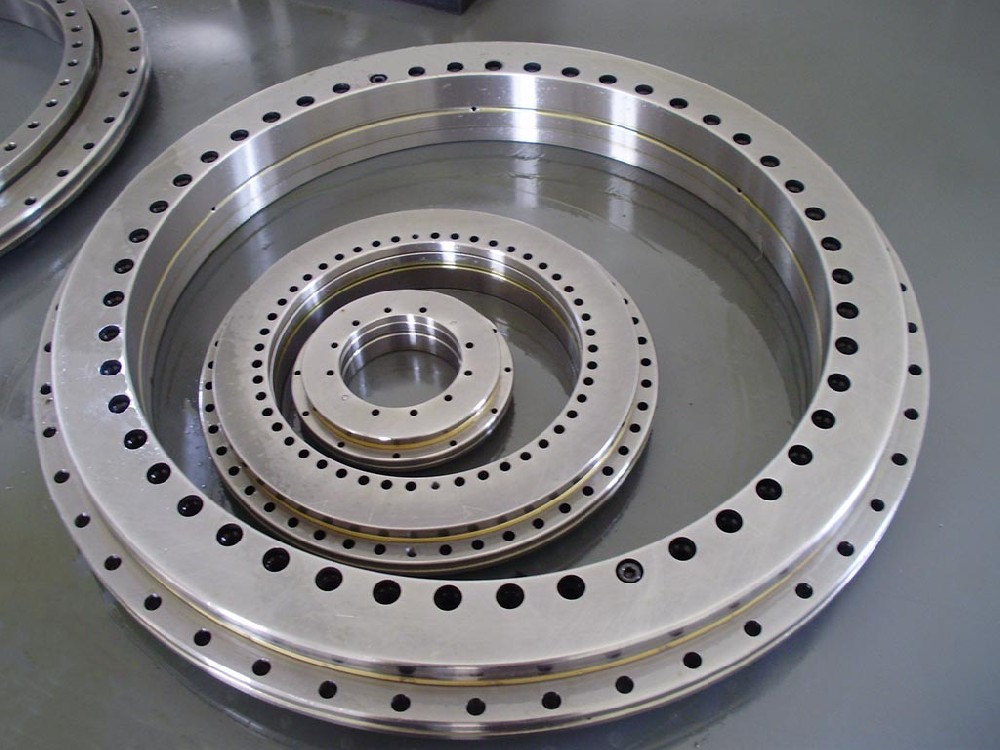

HRT series high-precision turntable bearings break through the traditional bearing selection and arrangement. One set of bearings can meet the requirements of the turntable to withstand combined loads, greatly simplifying the structure of the turntable and reducing design, installation, maintenance and costs. The combination of a radial roller set and two axial thrust roller retainer assemblies makes the structure compact, saving space for the overall structural design of the turntable; the bearings are arranged with mounting holes, making installation extremely convenient; the bearings are preloaded before leaving the factory, and high rigidity and high rotation accuracy can be achieved without adjusting the clearance; the inner and outer rings of the bearings are equipped with oil filling holes, which are convenient for regular oil filling and maintenance; the rotation accuracy of HRT turntable bearings can reach up to 1.5μm, which is much higher than that of ordinary bearings.

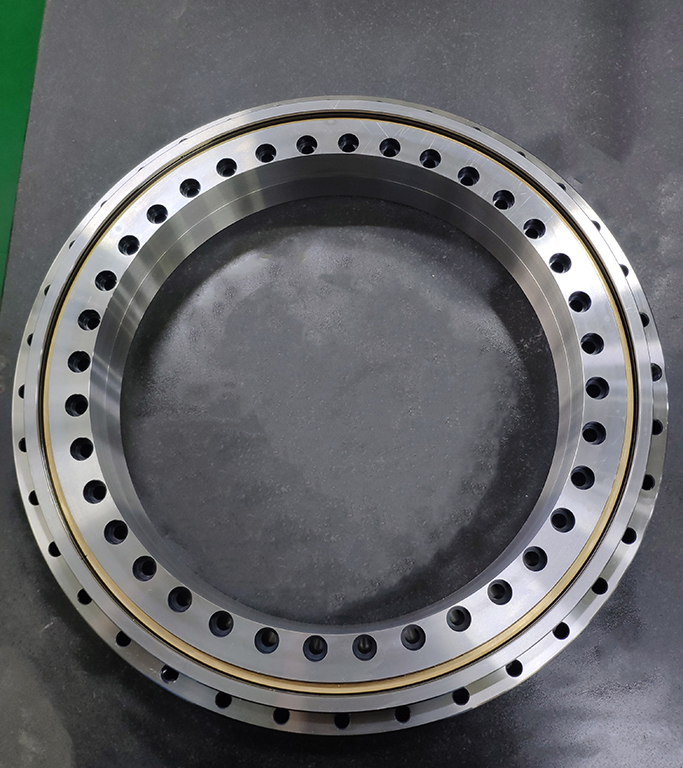

HRT turntable bearings consist of a thrust/radial seat ring, a thrust/radial shaft ring, a thrust washer, two needle roller retainer assemblies and a set of radial cylindrical rollers. The seat ring and shaft ring have evenly distributed mounting screw holes. This type of bearing has high axial and radial load capacity, high tilting stiffness and extremely high accuracy. It is suitable for rotary tables, as well as bearing configurations in measurements and experiments. This type of bearing also has relatively high requirements for matching equipment parts. The tightening torque of the mounting screws needs to be controlled during installation.

HRTS high-speed series turntable bearings have the same appearance and structural dimensions as HRT standard series turntable bearings, but their special internal structure design enables them to have a higher limit speed, and the friction is low and uniform in the entire speed range. Therefore, they are suitable for applications similar to HRT standard series but requiring lower friction and higher speed, such as bearing applications for direct drive shafts.

HKLDF thrust angular contact ball series turntable bearings adopt a double-direction 60° contact angle and double-row ball structure design, so they can withstand radial loads, double-direction axial loads and overturning moments; the special structure of the cage design makes it have higher strength and lower friction torque; therefore, this series of bearings is particularly suitable for ultra-high speed, long-term operation and high rigidity and precision requirements.

The measurement of angular displacement of turntable bearings plays a very important role in modern industry, especially in the machine tool industry, which often has high requirements for the rotation angle of the workpiece, which requires accurate measurement and control of angular displacement. At present, the commonly used methods for measuring angular displacement are grating encoders, magnetic grating encoders, etc., while the Heidenhain AMOSIN steel grating measurement system we use has the advantages of high accuracy (maximum angular resolution ≤ 2 arc seconds), pollution resistance, no electromagnetic influence, strong environmental adaptability, etc. At the same time, because it is installed on the HRT turntable bearing, the combined bearing has extremely high rotation accuracy and can withstand axial loads, radial loads and overturning moments at the same time. It is very suitable for high-precision CNC turntables, dividing heads in the machine tool industry, and scientific research experiments and measurements and other fields with high requirements.