YRT turntable bearing system can be mainly used in CNC machine tool manufacturing industry. As its core components, the domestic market demand for YRT series bearings is still heavily dependent on Chinese imports, and the precision parameter selection standards of domestic YRT turntable bearings are also based on international manufacturers. Since the beginning of the 21st century, especially with the launch of our country's "High-end CNC machine tools and basic technology manufacturing process equipment" project, the development of my country's mechanical engineering equipment industry has been greatly promoted, and the historical process of the development of the machine tool industry with "high speed, precision, composite and intelligent" has been further accelerated by students. So how is the YRT turntable bearing installed through analysis?

The bearing enters the housing.

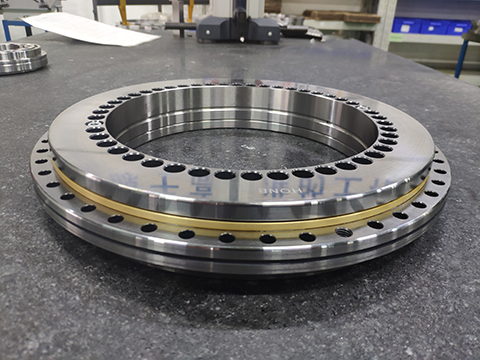

The outer diameter of the YRT turntable bearing matches the clearance of the bearing seat.

Tighten the outer ring mounting screws in sequence in a cross manner.

The table of the CNC turntable is pressed on the end face of the bearing.

The YRT turntable bearing can be installed as another part of the end face with the flange.

The outer diameter of the installation table is interference fit with the inner diameter of the bearing.

Align the mounting holes on the turntable bearing and the turntable.

Tighten the inner ring connecting screws crosswise once.

The connecting screws pass through the flange and the bearing is locked on the turntable surface.

If the bearing is extremely difficult to turn, loosen the mounting bolts and retighten them in three steps in a cross-sequence to eliminate bearing deformation.