Product Overview:

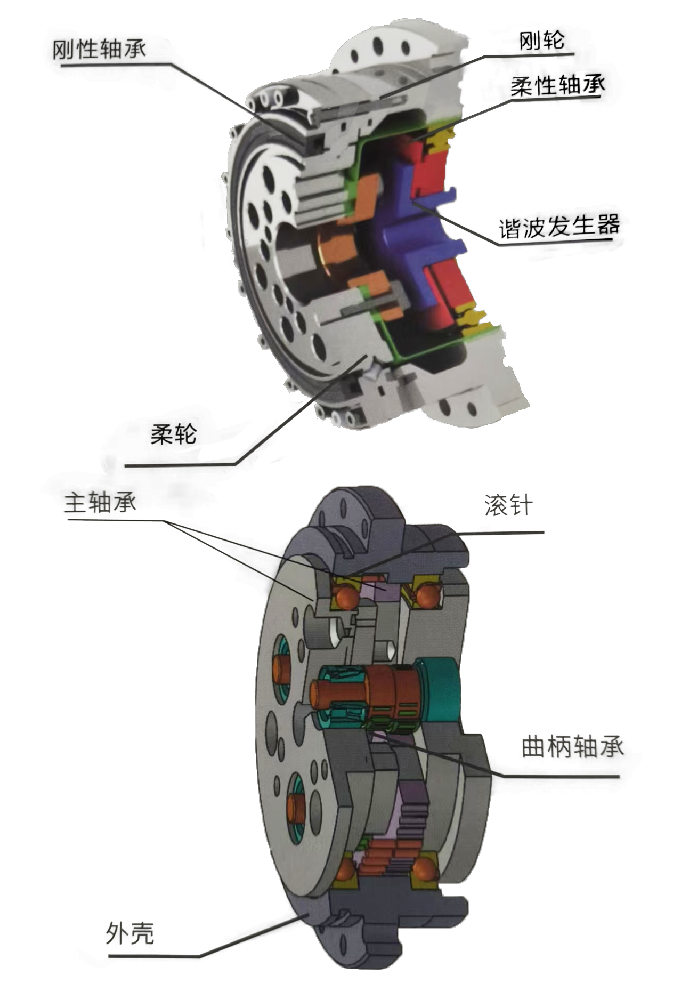

Robot reducers have the characteristics of high precision, high rigidity, high load, high speed ratio, high life, low inertia, low vibration, low noise, low temperature rise, compact structure, and simple installation. There are two main types of reducers currently used in the field of robot reducers, one is harmonic reducer and the other is Rv reducer.

Bearings, as one of the most core components in reducers, are also divided into the following categories according to reducers, namely cross roller bearings for harmonic reducers, flexible bearings for harmonic reducers, and angular contact ball bearings for Rv reducers. Cross roller bearings for harmonic reducers include four series, CSG (CSF) series, CSD series, SHG (SHF) series, and SHD series. The naming method adopts the naming of reducers; the flexible bearings for harmonic reducers are named HYR, and the main bearings of RV reducers are named Rv.

Crossed roller bearings for harmonic reducers

Crossed roller bearings for harmonic reducers are divided into two categories according to their use occasions: split outer ring, integral inner ring, and integral outer ring and inner ring. The rolling elements are cylindrical rollers, which are arranged vertically at 90° in a V-shaped raceway. This type of bearing can simultaneously withstand loads in various directions such as axial load, radial load and overturning moment. The bearing has high precision, high rigidity and composite load capacity.

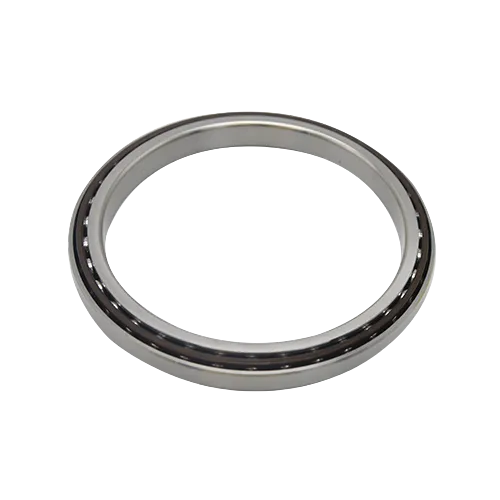

Flexible bearings for harmonic reducers

HYR flexible bearings mainly withstand alternating bending stress and torque stress. Due to its relatively thin wall thickness, it is more likely to deform when it cooperates with the cam. The inner and outer rings and rolling elements of the bearing are made of high-carbon chromium bearing steel, and the retainer is a nylon integral retainer, which is specially used in the harmonic generator part of the harmonic reducer.

Angular contact ball bearings for RV reducers

RV reducer bearings are mostly non-standard in size, consisting of an outer ring, an inner ring, an integral retainer and a set of precision steel balls, with a contact angle of 40°; the bearings can simultaneously bear radial loads and axial loads in one direction, or pure axial loads in a single direction. Such bearings are often used in pairs in a back-to-back configuration; the bearing has a small cross-section, saving the installation space of the host; the retainer is made of engineering plastics with added glass fiber, which greatly reduces the weight of the entire bearing and improves the strength and operating temperature of the material (the retainer is temperature-resistant to 120°). Mainly used in the main support part of the RV reducer.