In view of the low friction and high-speed precision of bearings, the factors and key points affecting low friction and high-speed precision are analyzed. Taking new energy drive motors as an example, the requirements for low friction and high speed are listed.

Bearings are indispensable key basic components in modern industry and are known as the "heart" of mechanical equipment. Their load-bearing capacity will directly affect the technical level of equipment and is an important standard for measuring a country's scientific and technological and industrial strength. However, with the development and evolution of downstream industries, traditional rolling bearings are becoming more and more "overwhelmed". Large-scale and high-speed equipment have become a trend, and more stringent operating conditions and high reliability requirements have posed new challenges to bearing technology.

After more than 40 years of development, my country's bearing industry has made great progress in bearing products and manufacturing levels, and has a considerable scale and development foundation. With the advancement and development of technology, higher and higher requirements are also put forward for the performance and requirements of bearings. This article mainly discusses the development trend of bearing technology from the two aspects of low friction and high-speed precision.

Low friction

The challenge of the new generation of friction reduction design is to further reduce the already extremely low friction torque, with the highest reduction even reaching 80%.

In new energy vehicle applications, low-friction bearings are required to reduce energy consumption losses; in aerospace application requirements, bearings are required to have low-temperature friction resistance, etc.

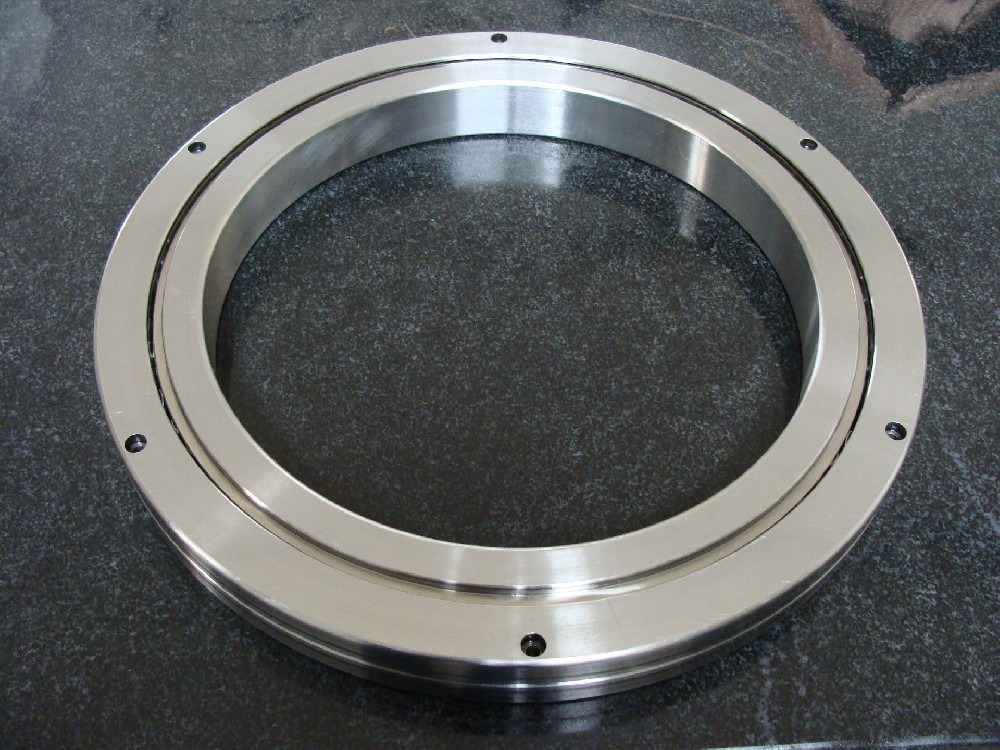

Bearing friction is not constant, it depends on certain friction phenomena that occur in the lubricating film between rolling elements, raceways and cages. The technical indicators that affect the low friction of bearings mainly include aspect ratio, bearing clearance, bearing wall thickness, and special designs for extreme (limit) working conditions.

High-speed precision

The high and low speeds of bearings are not measured by the rotation speed of the bearing itself, but by its linear speed. Generally, bearings with a linear speed of 60 meters per second can be considered high-speed bearings. High-speed bearings usually have a smoother surface and a very small distance between the inner and outer rings, so the requirements for bearing precision are higher. The main factors affecting bearing high speed include bearing type, size, load, lubrication method, cage material and type, bearing load, preload, drive method, bearing clearance and bearing combination.

Although the gap between China and the world's advanced enterprises is gradually narrowing, it still needs to work hard to be detailed, practical and strong.