Bearings in machinery mainly play the role of supporting and reducing friction. For high-speed applications, when radial loads, axial loads, torque loads and other multi-directional loads are simultaneously applied, cross roller bearings are generally selected.

The inner and outer ring sizes of cross roller bearings are minimized, especially the ultra-thin structure is close to the limit of small size, and has high rigidity, so they are widely used in the joints or rotating parts of industrial robots, rotary tables of machining centers, rotating parts of manipulators, precision rotary tables, medical instruments, measuring instruments, IC manufacturing devices, etc.

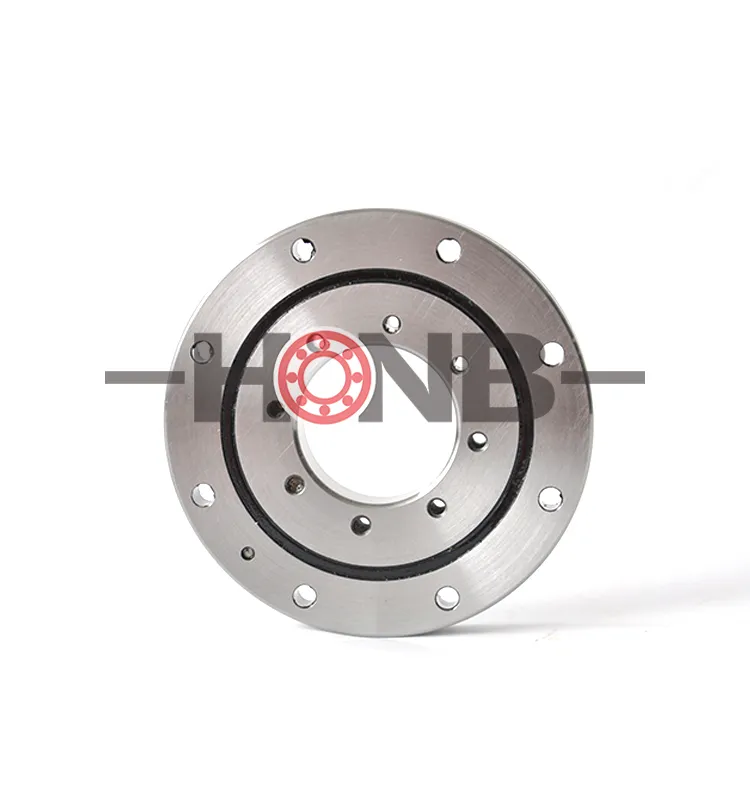

HRU type (integral inner and outer rings, with mounting holes), since both the outer and inner rings have mounting holes, no fixed flange and support seat are required during installation. In addition, since both the outer and inner rings are integral structures, installation has almost no effect on performance, so stable rotation accuracy and torque can be obtained. Suitable for occasions where the outer and inner rings rotate.

HRB type (integral inner ring, split outer ring) This model is the basic type of cross roller bearings. The outer ring is divided into two pieces, and the inner ring is an integral structure. It is most suitable for occasions requiring inner ring rotation accuracy.

HRBH type (integral inner and outer rings, ultra-thin), due to the ultra-thin design and the lack of mounting holes on the outer and inner rings, flanges and support seats are required for installation. In addition, since the outer and inner rings are integral structures, installation has no effect on performance, so stable rotation accuracy and torque can be obtained, which is suitable for occasions where the outer and inner rings rotate but the size is required to be miniaturized.

HRAU type (integral inner and outer rings, ultra-thin), this model is a compact type that reduces the thickness of the inner and outer rings of the HRB type to the limit. It is most suitable for parts that require light weight and compact design, such as the rotating parts of robots and manipulators, and can be used in occasions where the inner and outer rings rotate.

HSX type (integral inner ring, split outer ring, ultra-thin), under the same shaft diameter, this type has a smaller cross-sectional size than the HRB type. Due to the ultra-thin design, the outer and inner rings have no mounting holes, and flanges and support seats are required for installation. It is suitable for applications where the inner ring rotates.

XR/JXR type: The use of large taper angles and tapered geometry design makes the overall effective span of the bearing larger, while also saving space and material costs. Therefore, crossed tapered roller bearings have higher anti-overturning moment capacity, higher rotation accuracy and maximum speed, and are ideal for bearings used in high-speed vertical lathes, vertical boring machines, vertical grinders and other machine tool turntables.