Current status of Hongyuan robot reducer special bearings Robot bearings mainly include three categories: harmonic reducer bearings, RV reducer bearings, and humanoid robot bearings. According to the data from MiTu Consulting's "2024 Humanoid Robot Industry Chain White Paper", the value of bearings in humanoid robots accounts for 5.50%. Bearings are the core components of humanoid robot actuators, which directly determine the motion accuracy, load-bearing capacity and stability. It is estimated that the annual demand for robot bearings will reach hundreds of millions of sets in 2030. Companies such as Japan and Germany occupy about 60% of the global industrial robot market share. They control the industrial robot bearing industry chain and costs by mastering the technologies of the component end, the body, and the integrated application end. The robot reducer bearings developed by Hongyuan Bearing have the characteristics of high precision, low friction and long life. The overall technical level of this product is at the leading level in China, and various performance indicators have reached the same level as Japanese products. The main competitors are foreign THK, IKO, HD, etc. Hongyuan has been developing robot bearings since 2010 and realized exports in 2020. At present, it has developed 5 major series including SHF (LHS), CSF (LSS), CSD, SHD, RV, etc., with a monthly production capacity of 300,000 sets, occupying more than 90% of the domestic precision reducer bearing market. The main manufacturers served include Suzhou Green, Zhejiang Laifu, Dazhu Laser, Guangzhou Haozhi, Foxconn, Nanjing Estun, Midea and other well-known domestic companies, and exported to Nidec Group. At present, the market for humanoid robot bearings has doubled, breaking the long-term monopoly of similar foreign products.

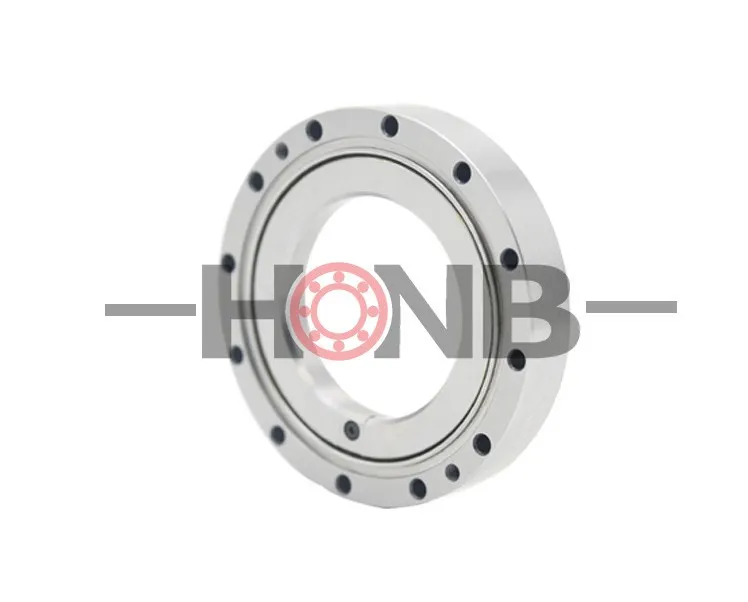

CSG (CSF) type (split outer ring, integral inner ring)

The outer ring is divided into two pieces, and the inner ring is an integral structure. Flanges and bearing seats are not required during installation. It is mainly used in the output part of CSG and CSF series reducers.

CSD type (integral outer ring, integral inner ring)

The outer ring and inner ring are both integral structures, and the outer diameter size is the same as that of CSG type. It has higher rigidity than CSG type bearings and is mainly used in the output part of CSD series reducers.

SHG (SHF) (integral outer ring, integral inner ring)

The outer ring and inner ring are both integral structures, which can obtain stable rotation accuracy and torque. They are mainly used in the output part of SHG and SHF series reducers.

SHD type (integral outer ring, integral inner ring)

The outer ring and inner ring are both integral structures, and the height is lower than that of SHG, which saves the installation space of the reducer. It is mainly used in the output part of SHD reducer. (If you need relevant technical information of SHD series bearings, please contact our company's technical personnel)

Flexible bearings for harmonic reducers

HYR flexible bearings mainly bear alternating bending stress and torque stress. Due to its relatively thin wall thickness, it is more likely to deform when it cooperates with the cam. The inner and outer rings and rolling elements of the bearing are made of high-carbon chromium bearing steel, and the retainer is a nylon integral retainer, which is specially used in the harmonic generator part of the harmonic reducer.

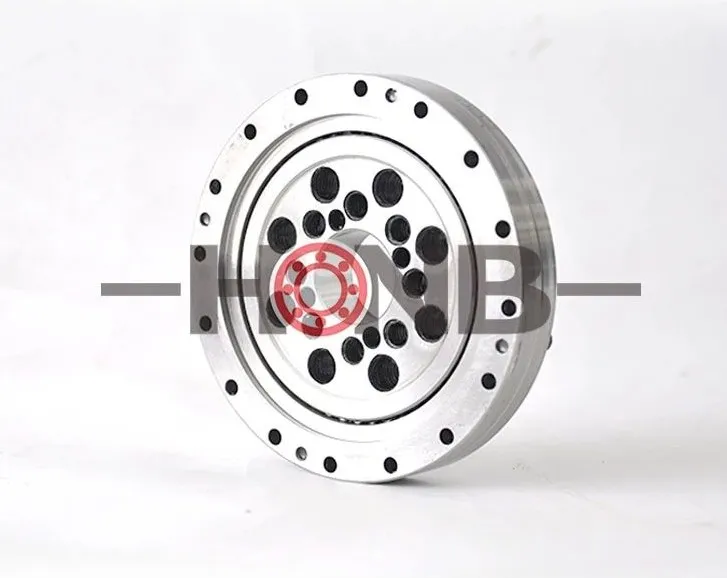

Angular contact ball bearings for RV reducers

RV reducer bearings are mostly non-standard in size, consisting of an outer ring, an inner ring, an integral retainer and a set of precision steel balls, with a contact angle of 40°; the bearings can simultaneously bear radial loads and axial loads in one direction, or pure axial loads in a single direction. Such bearings are often used in pairs in a back-to-back configuration; the bearings have a small cross-section, saving installation space for the host; the retainer is made of engineering plastics with added glass fiber, which greatly reduces the weight of the entire bearing and improves the strength and operating temperature of the material (the retainer is temperature-resistant to 120°). Mainly used in the main support part of the RV reducer.