Thrust bearings are a special type of sliding bearings, which are double-row cylindrical roller bearings composed of a pair of mutually meshing bearing parts. Thrust bearings have a simple structure and do not require lubrication or sealing to prevent contamination and corrosion. They are suitable for applications that require large shaft loads but do not rotate at high speeds. Thrust bearings are divided into thrust ball bearings and thrust roller bearings.

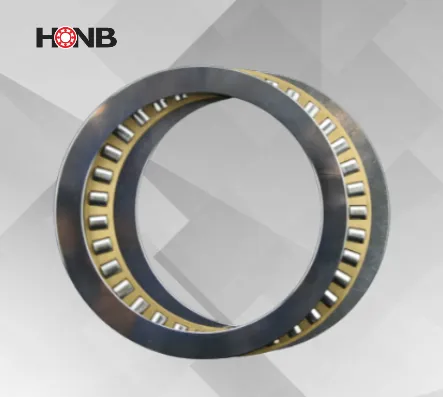

Thrust roller bearings are designed to meet the requirements of heavy loads and high loads, and have the characteristics of light weight, large load-bearing capacity, small friction factor, and wide temperature variation range. Under heavy loads, low speeds or light loads, radial loads can be maintained without axial movement, and large axial loads can be borne. Thrust bearings are widely used in various machines such as machine tool spindles, internal combustion engine cylinders, ships, and automobile engines. In modern machine tools, the application of thrust bearings has become quite common - usually multiple thrust bearings with two or three rollers can be used in machining centers, etc.

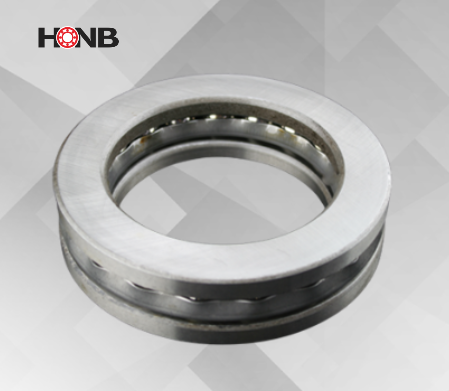

Thrust ball bearings are mainly composed of a bearing seat and a set of spherical rollers. The inner ring has two spherical rolling elements, which are installed on the two sides of the bearing seat, and the roller is connected to the raceway of the other end face through the inner ring. The bearing seat is one of the two cylindrical holes fixed to the base by bolts, and a rotatable bolt is installed on it. The cylindrical hole is cylindrical and has a certain distance relative to the two spherical rolling elements. It is the largest gap between the bearing seat and the spherical rolling element. The spherical roller is composed of a raceway with a thread or gear connecting the spherical rolling element and contacting the other end face, and corresponding to the inner ring, the roller tooth shape is a semi-conical boss (or "inner concave spherical") instead of a truncated cone (or "outer convex spherical").

Thrust roller bearings are designed to meet the requirements of heavy loads and high loads. They have the characteristics of light weight, large load-bearing capacity, small friction factor, and wide temperature change range. Under heavy loads, low speeds or light loads, radial loads can be maintained without axial movement, and large axial loads can be borne. Thrust bearings are widely used in various machines such as machine tool spindles, internal combustion engine cylinders, ships, automobile engines, etc. In modern machine tools, the application of thrust bearings is quite common - usually multiple thrust bearings with two or three rollers can be used in machining centers, etc.