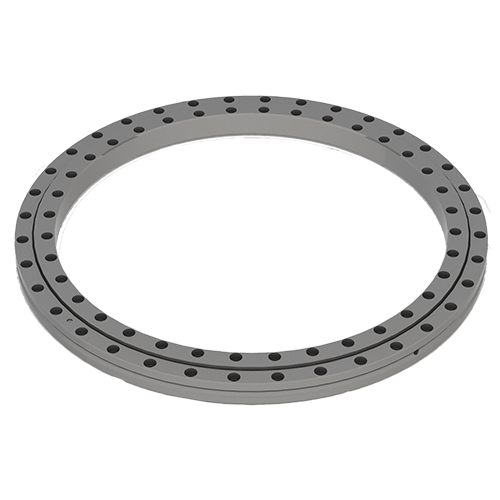

When the precision turntable bearing leaves the factory, its bearing raceway is filled with high-quality lithium-based grease (GB/T7324-1994).

The tooth surface should be cleaned of debris regularly and coated with corresponding grease.

After the precision turntable bearing runs for the first 100 hours, the bolt preload should be checked.

Pay attention to the operation of the precision turntable bearing during use. If noise, impact, or sudden increase in power is found, the machine should be stopped immediately for inspection and troubleshooting. If necessary, it needs to be disassembled for inspection.

It is forbidden to flush the precision turntable bearing directly with water during use to prevent water from entering the raceway and to prevent hard foreign objects from approaching or entering the tooth meshing area.