In the logistics and machining industries, industrial robots are the key to efficient operation. They can complete a series of complex movements with extremely high efficiency and precision. Behind this, precision bearings play an indispensable role. Whether it is the joints of the robot or the key positions of power transmission, they are inseparable from the close fit of bearings. There are many types of bearings commonly used in industrial robots. Hongyuan Bearings stands out in various bearing applications with its excellent quality and performance.

The rollers of the crossed roller bearings are arranged vertically at 90 degrees, giving it the significant advantages of high rigidity and high precision. Hongyuan crossed roller bearings perform well in occasions where high load and high-precision positioning are required, such as robot joints, rotating platforms, and mechanical wrists. It can withstand radial and axial loads, provide solid and reliable support for the key parts of the robot, ensure the positioning accuracy of the robot in complex operations, and help industrial robots complete various high-precision tasks.

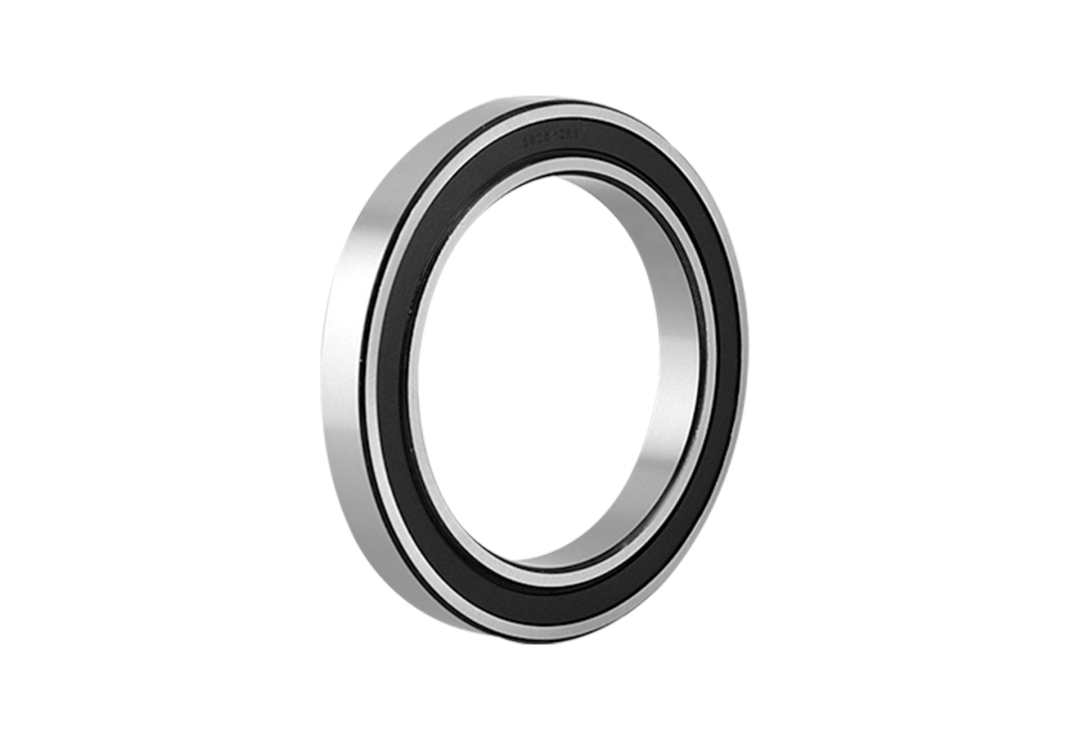

Thin-walled deep groove ball bearings have a small friction coefficient, high limit speed, thin design, and light weight. This unique design makes it perform well in the arms, joints and other parts of industrial robots. These parts need to withstand multiple alternating loads. Hongyuan thin-walled deep groove ball bearings can not only easily handle this task, but also rely on their excellent manufacturing process to ensure the flexibility and stability of the robot during movement, making every movement of the robot smooth and free.

Thin-walled angular contact ball bearings can withstand axial loads and radial loads in a single direction. Installing them in pairs in the robot reducer and drive device can further improve the load-bearing capacity and operating stability. Its low friction, low noise and high rigidity after pairing provide reliable guarantees for the efficient drive of industrial robots, help robots achieve precise and flexible movements, and greatly improve the working efficiency and reliability of industrial robots in complex production environments.

Tapered roller bearings are mainly used in RV reducers and robot joints in industrial robots. In RV reducers, thin-walled tapered roller bearings are used for eccentric shaft positioning and main body support, providing high load and high rigidity in limited space to ensure stable operation and transmission. At the robot joints, it can withstand radial and axial combined loads to ensure flexible and precise movement of the joints. It can also cope with large axial force scenarios such as vertical joints, prevent axial movement, and improve stability and reliability.

There are many types of industrial robot bearings, and multiple factors need to be considered when selecting, such as the load direction, load size, shaft speed, bearing life, bearing accuracy, bearing material, bearing sealing performance and bearing thermal stability of the installation part. With rich industry experience, Hongyuan Bearing recommends that when selecting bearings, the required axial and bearing loads should be accurately determined first, and the specific bearing type should be determined through scientific motion schemes and simulation calculations. For locations with limited installation space but high precision and high load, Hongyuan cross roller bearings or thin-walled bearings are ideal.

Industrial robots are complex and sophisticated equipment that need to complete multiple operations such as rotation, handling, and assembly, which determines their diverse needs for bearing types. Hongyuan Bearings, with its rich product line, excellent quality and performance, meets the needs of different parts and working conditions of industrial robots. When selecting bearings, the reasonable selection of bearings based on actual conditions can give full play to the performance advantages of industrial robots and provide solid guarantees for the efficient production of enterprises.