Xinhua News Agency, Zhengzhou, March 6 (Reporter Han Chaoyang) Slowly "hide the handkerchief", quickly "show the handkerchief", swing the arm "turn the handkerchief"... accompanied by the joyful and festive Yangko and the rhythmic gongs and drums, 16 humanoid robots dressed in flowery cotton jackets, with uniform movements to show a series of "hand skills".

On the stage of this year's Spring Festival Gala, humanoid robots twisting Yangko and turning handkerchiefs amazed the audience and shone brightly. But do you know? The coordinated movement of the human body is inseparable from the joints, and the "joints" of the robot are inseparable from a seemingly inconspicuous component-bearings. As an indispensable component in the rotating joints of humanoid robots, it mainly bears the role of supporting, guiding rotation and reducing friction, which can make the robot's joints more stable during movement and reduce energy loss.

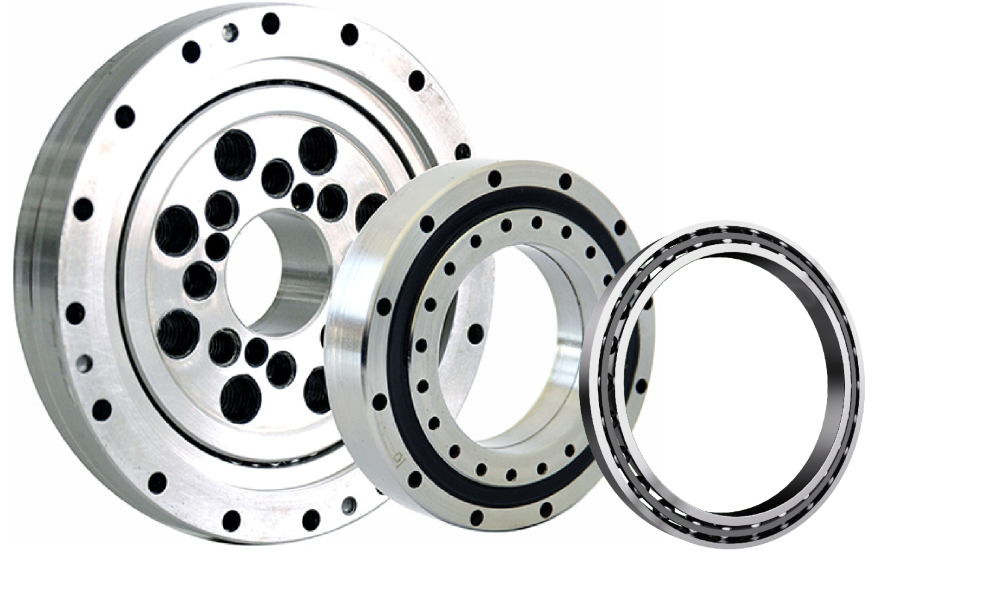

This is a robot bearing product of Luoyang Hongyuan Bearing Technology Co., Ltd. Xinhua News Agency

It is understood that in Luoyang, Henan, the turntable bearings and cross roller bearings produced by Luoyang Hongyuan Bearing Technology Co., Ltd. (hereinafter referred to as "Hongyuan Bearing"), a national key specialized "little giant" enterprise, occupy more than 80% of the domestic market, and robot bearings occupy more than 90% of the domestic market, which can be called the "hidden champion" in the field of precision bearing manufacturing.

"The harmonic reducer is used in the 'joint' part of the industrial robot. It converts high-speed input into low-speed, high-torque output through the elastic deformation and tooth meshing of the flexible wheel, similar to slowly pulling heavy objects with a rubber band to achieve the smooth operation of the robot." Lv Ruifang, technical director of Hongyuan Bearing, introduced, "Our precision bearings can make the harmonic reducer more accurate and the product more durable."

In the Hongyuan Bearing production workshop in Mengjin District, Luoyang City, pick up the processed special bearings for harmonic reducers. The bearings are divided into inner and outer circles. The appearance looks full of texture. Gently turn it by hand, it is both smooth and full of damping.

Little did they know that 14 years ago, when a scientific research institution found Hongyuan Bearing with a sample of special bearings for robot harmonic reducers, the company's technical team had no idea what it was. "I had never seen it before, so I asked around and figured out the process bit by bit. I finally had a more competitive new product, and I had to keep it in my hands." Wu Qiaoling, general manager of Hongyuan Bearing, said, "At the beginning, foreign bearings of the same type ran fine for 3 years, but ours began to lose accuracy in less than 1 year. After 7 years of thousands of trials and errors, our products are of the same quality as foreign bearings. Since 2020, our robot bearings have been exported to Japan and other countries." Today, the company has more than 80 R&D personnel among its more than 500 employees, and more than 8% of its revenue is spent on technology research and development each year, and most of its profits are used to upgrade machinery and equipment. At present, the number of R&D personnel is still growing rapidly, and the replacement cycle of machinery and equipment is still shortening, always ready to meet market opportunities. At the beginning of the Year of the Snake, Hongyuan Bearing stepped up efforts to acquire land and build factories. "Orders for humanoid robot bearings have grown explosively this year. We have received orders worth 120 million yuan so far. Production has been scheduled until June. We will strive to put the new factory into production in May, doubling our production capacity," said Wu Qiaoling.