Precision slewing bearings are medium and large bearings with a special structure that can withstand comprehensive loads such as large axial loads, radial loads, and overturning moments at the same time. Under normal circumstances, the precision slewing bearing itself has installation holes, lubricating oil holes and sealing devices, which can meet the needs of different working conditions; It is widely used in precision marine equipment, precision grinding machines, lathes, gear shaping machines, laser chucks, medical equipment rotary tables and indexing plates, machine tools, radars, wind power generation and tank turrets, etc., and is widely used.

According to the structure of the rolling elements, the precision slewing bearings are divided into two series: cross roller slewing bearings and four-point contact ball slewing bearings. Install the seal, equip with oil filling cup, adjust the clearance torque in a small range, and the precision can reach P5/P4/P2 level to meet the needs of various working conditions.

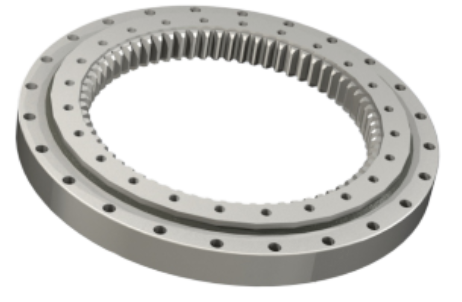

External gear type four-point contact ball slewing bearing

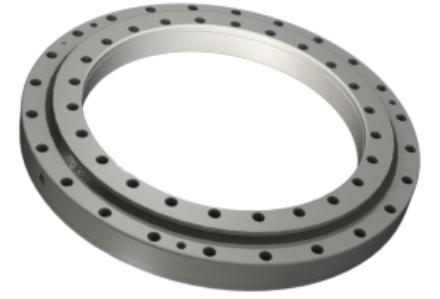

Internal gear four-point angular contact ball slewing bearing

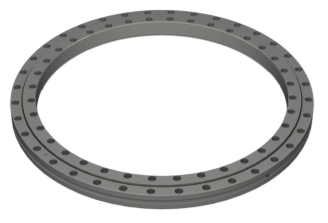

Four-point contact ball slewing bearing without teeth

External gear type cross roller bearing slewing bearing

Internal tooth type cross roller bearing slewing bearing

Non-toothed crossed roller bearing slewing bearing