1. Excellent rotation accuracy

The internal structure of the crossed roller bearing adopts rollers arranged vertically and intersecting each other at 90°. There are spacers or spacers between the rollers, which can prevent the rollers from tilting or rubbing against each other, and effectively prevent the rotation torque. Increase. In addition, there will be no one-sided contact phenomenon or locking of the rollers; at the same time, because the inner and outer rings are divided, the gap can be adjusted, and high-precision rotary motion can be obtained even if preload is applied.

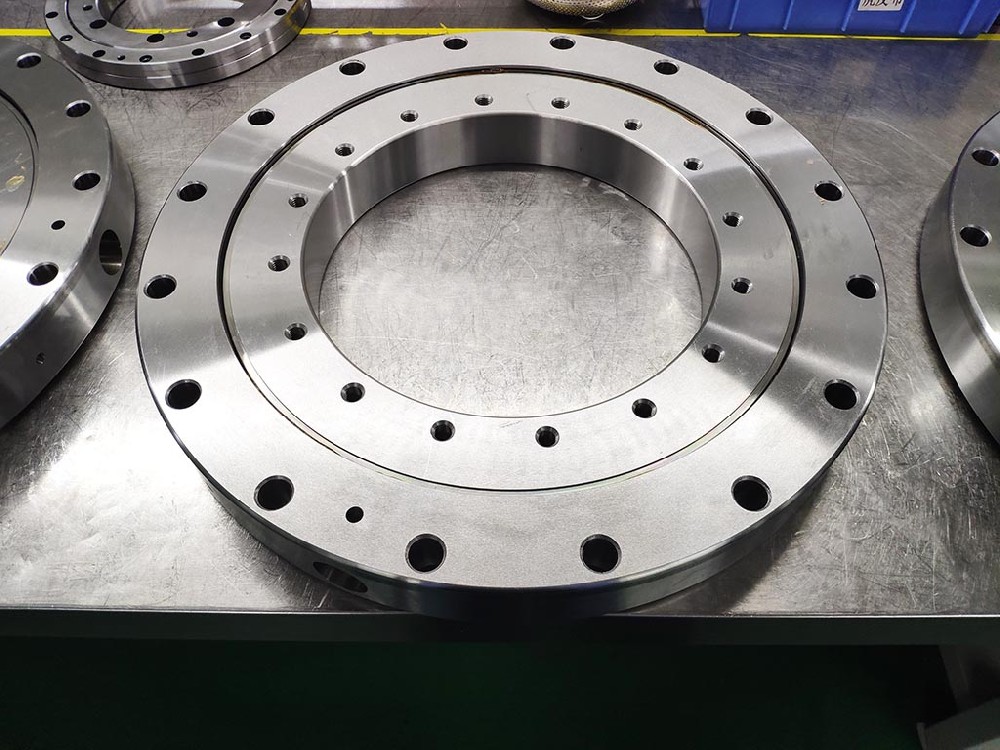

2. Simplified operation and installation

The outer ring or inner ring divided into two parts is fixed together after the rollers and cages are installed, so the installation operation is very simple.

3. Bear large axial and radial loads

Because the rollers are vertically arranged on the 90° V-groove rolling surface through the spacer, this design enables the crossed roller bearing to withstand large radial loads, axial loads and moment loads, etc. direction load.

4. Significantly save installation space

The size of the inner and outer rings of the crossed roller bearing is minimized, especially the ultra-thin structure is a small size close to the limit, and has high rigidity, so it is most suitable for the joints or rotating parts of industrial robots, and the rotation of machining centers It can be used in a wide range of applications such as worktables, manipulator rotating parts, precision rotary tables, medical instruments, measuring instruments, and IC manufacturing equipment.