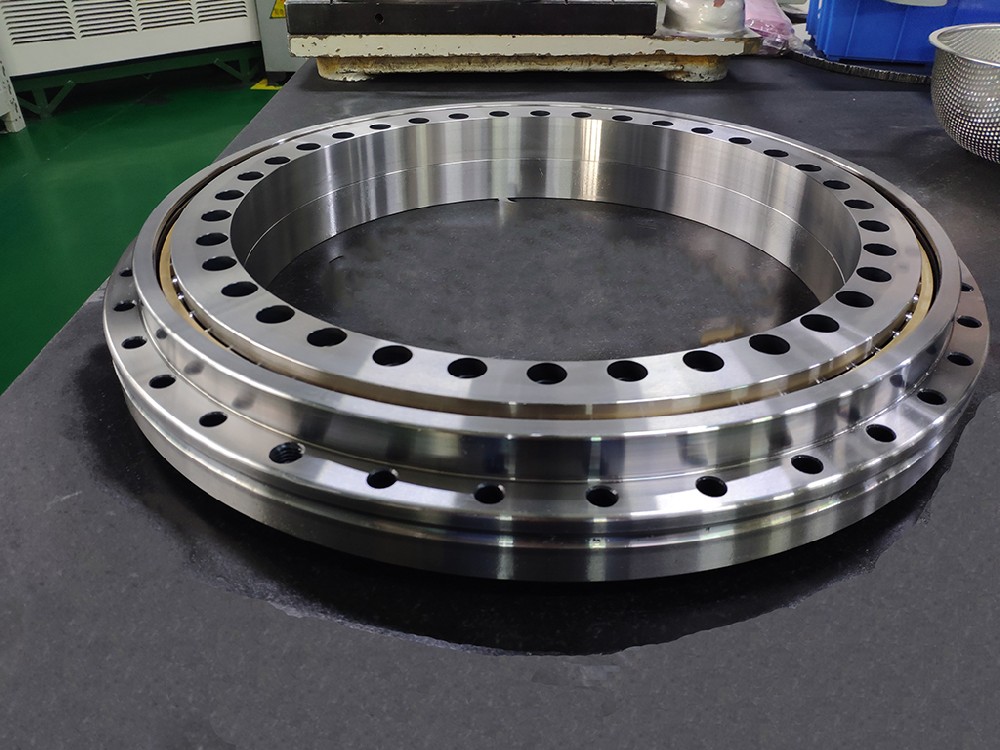

ZKLDF series thrust angular contact ball bearings include an integral outer ring, two inner rings and two sets of steel balls and cage assemblies, with a contact angle of 60 degrees. The outer ring and inner ring are equipped with mounting holes, which are convenient for installing and fixing the bearings through connecting bolts. The bearings themselves are fixed by connecting bolts to ensure installation, transportation and handling. There are sealing covers on both sides of the ZKLDF thrust angular contact ball series turntable bearings to prevent the entry of external dirt and impurities and the leakage of internal grease. ZKLDF thrust angular contact ball series turntable bearings are lubricated with composite barium-based grease, and can also be relubricated through the oil holes on the outer ring. ZKLDF thrust angular contact ball series turntable bearings adopt a two-way 60-degree contact angle and a double-row ball structure design, so they can withstand radial loads, two-way axial loads and overturning moments; the brass cage design with a special structure makes it have higher strength and lower motor torque; therefore, this series of bearings is particularly suitable for ultra-high speed, long-term operation and occasions with high requirements for rigidity and precision. ZKLDF has the advantages of low friction, high rotation accuracy, high speed limit, etc. It can bear high axial and radial loads and has high tilting stiffness. This kind of bearing is particularly suitable for applications in the field of composite loads and precision, and is widely used in machine tool rotary tables, grinding heads and various test equipment.